Electrostatic septa

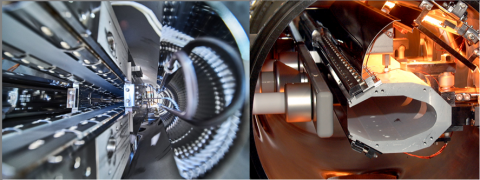

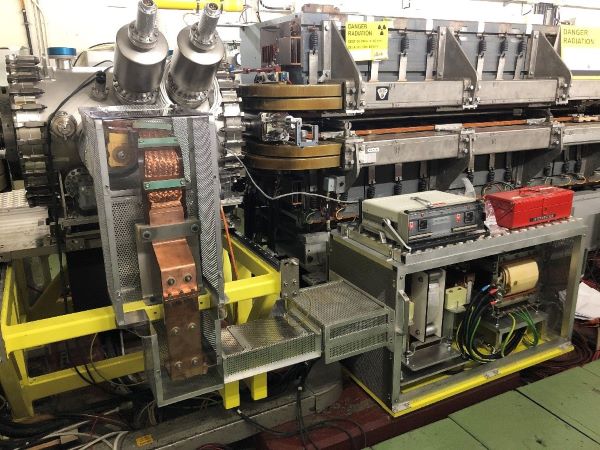

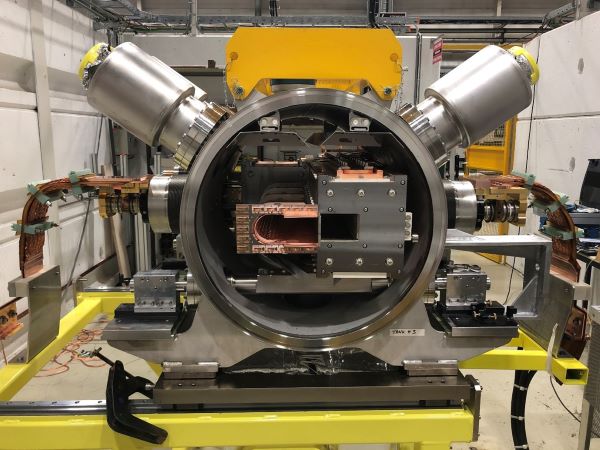

Electrostatic septa are devices that deflect particle beam using an electric field. This allows for only a very thin separation between the field free region and the high field region (see link for a general explanation). Recently the 5 electrostatic septa installed in the SPS were upgraded to improve their beam impedance as well as to improve their operation vacuum. To this end new impedance screens we designed and installed in each septum tank and these tanks were connected between each other using newly designed interconnects which preserve as well as possible the beam impedance. Vacuum was improved by the installation of ion pumps which are equipped with additional NEG cartridges. Together with the much improved location of these pumps, the pumping speed available in the septa vacuum vessels was significantly increased.

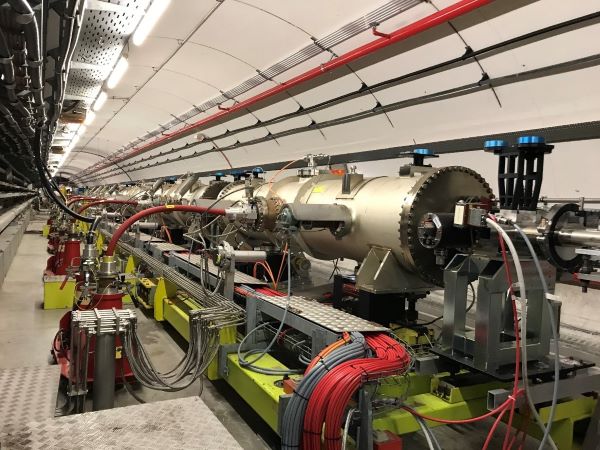

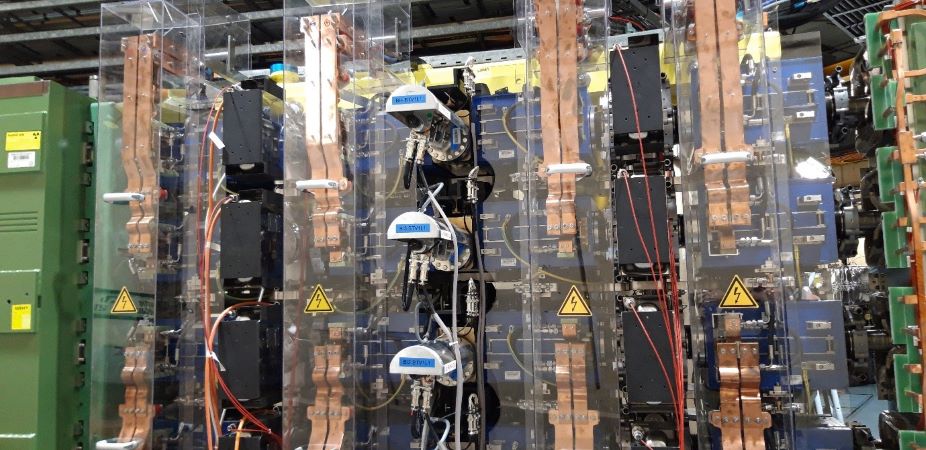

The image below shows the new set of electrostatic septa installed in the SPS, together with their High Voltage (HV) connections.